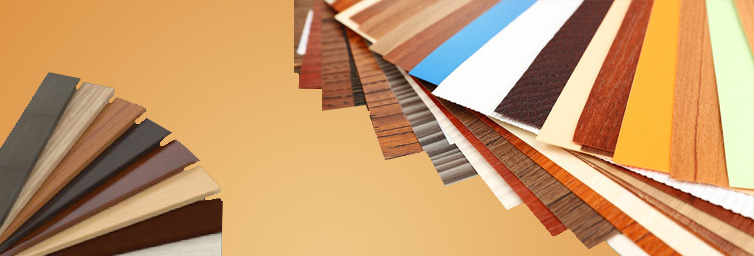

Laminate sheets

Laminates provide a better surface finish for furniture elements and also provide an attractive look for a very less price. Furniture like tabletops, cupboards, surfaces of chairs mostly uses laminates as the finish material.

Due to their availability of different types in the market, these days laminates are used in corporate offices, commercial complexes, residential buildings, restaurants, hotels, etc... for decorative purposes.

Laminate sheets are made by bonding together two or more layers of materials. Laminate sheets from plastics are glued to wood to make the surface aesthetic. These sheets are manufactured by laminating different types of papers with formaldehyde. The core sheet consists of Kraff paper with phenol formaldehyde (PF) and below it, a barrier paper is provided. Above the Kraff paper, a tissue paper is impregnated with FF melamine formaldehyde (MF) resin is provided which gives protection and also enhances abrasion resistance. Then, these laminates are bonded to wooden surfaces with suitable glue and pressing for some time finishes the process.

Types of Laminates

There are different types of laminated sheets available in India based on the manufacturing process, usage, surface finish, thickness, and advanced properties.

Laminates based on manufacturing process:

High-Pressure Laminate (HPL):

The layer of the laminate adheres to substrate under pressures of 70 to 100 bars at temperatures of 280° to 320° Fahrenheit using adhesives. The laminates are available in thickness 0.8 mm, 1.0 mm and 1.5 mm in standard sizes 1.2 m x 2.5 m. These laminates are most durable, flame retardant, and consists high level of resistance to heat and chemicals.

Low-Pressure Laminate (LPL):

The layer of the laminate adheres to substrate under pressures of 20 to 30 bars at temperatures of 335° to 375° Fahrenheit without using adhesives. These laminates are less durable, thinner than HPL, flame retardant, resistant to heat and chemicals and comparatively very cheaper than HPL.

Laminates based on Usage:

Decorative Laminates:

These laminates are mainly used as furniture surface materials and commonly used to protect the wooden surfaces. They are available both in low pressure and high-pressure laminates and used for decorating walls, home interiors, etc. to provide an attractive appearance.

Industrial Laminates:

These laminates are specially made for industrial uses, which are very durable and high resistant to wear and tear. They are mainly used for electrical insulation purposes like in circuit boards.

Laminates based on thickness:

Compact Laminates: These laminates consist of thickness ranging from 3 mm to 30 mm, which are self-supporting and need not be glued to any other material.

Regular laminates: These laminates consist of thickness ranging from 0.6 mm to 1.5 mm, and these sheets are glued together using adhesives like fevicol by carpenters to substrate materials like plywood.

Laminates based on advanced properties:

Fire retardant laminate: These laminates are specially made for fire-prone areas by using fire resistant resin. It is used for decoration in fire-prone applications like kitchens, industries, airports, hospitals, public buildings, institutions, store fixtures, etc.

Electrostatic Dissipative laminate: These laminates are made with the unique feature of low electrical resistance and mainly used in the electrical assembly for manufacturing circuit boards. These provide a surface that will not attract dust or dirt particles and ideal for work-stations, hospitals, and medical laboratories.

Anti-Bacterial laminate: These laminates are made with antifungal and antibacterial properties, which can resist the growth of bacteria and pathogens. These are used in hospitals, bathrooms, day care centers, etc. where hygiene is very important.

Magnetic Laminate: It is an innovative laminate, which has a unique property of holding a magnet. These are high-pressure decorative laminates used in educational institutions, offices, hospitals, etc. for holding reports, charts, photographs, etc.

Laminates based on Surface finish:

Glossy finished laminate: It creates a glossy effect on the laminate surface and also creates print on it, can make the furniture look more eye-catching and attractive than other finishes. These laminates are used in the event industry, restaurants, hotels, and in clubs.

Matt finished laminate: It creates matt like finish, which gives a flat finish on the laminate surface. These are used in corporate and business offices, where a subtle but a stylish look is desired.

Metallic finished laminate: As the name itself says that it gives a metallic look to the laminate surface. These laminates are durable and used in commercial buildings and showrooms.

Texture finished laminate: These laminates are designed in such a way, where you can feel the texture or pattern printed on the decor paper. These are used in flooring, wall cladding, where a subtle and classy look is required.

Solid Colored laminate: These types of laminates are printed with one solid color without any print or patterns on it. These are most common laminate sheets and mainly used in kitchen countertops and bathroom areas.

Digital laminate: These are customized printed laminated sheets used in interiors for the artistic view.

Wood Grain Laminate: These laminates are designed in such a way that they look like real wood and extensively used in wooden floorings. They are made of both softwood and hardwood.

Leather laminate: These laminates sheets give a leather material look and are used in cabinets and other furniture elements.

Check Out: Types of Exterior and Interior Doors

Deepika Maheshwari

posted on Jul 21, 2020 10:44:48 AM