You have no items in your shopping cart.

Post Requirement

TMT steel bars have a crucial role in the construction of any structure.TMT bars stands for Thermo Mechanically Treated bars. Understanding the process of manufacturing TMT steel is an important part of the construction business.

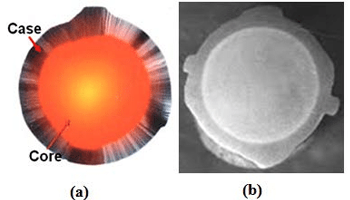

TMT bars have two cores- The outer hardcore and the inner softcore.

The quality of a TMT bar depends upon various factors such as,

- The quality of the material being used

- The machinery and equipment used for quenching and self-tempering process.

- The rolling mill which gives shape to the material.

There are five main processes that take place, which are:

- Extraction of material from iron ore

- Reinforced bar formation

- Quenching

- Self- tempering

- Atmospheric Cooling

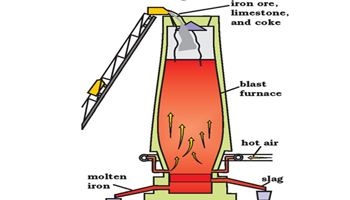

Extraction of Iron from its ore

Raw materials such as coke, iron ore, dolomite and limestone are put into a blast furnace and treated with hot gases while in their molten form. The molten state of iron is pre-treated and converted into steel. The chemical composition of the steel is then refined by passing through ladle heating. The molten form is then poured into a casting machine to produce the desired shape.

Shaping into a reinforced bar

The molten steel is heated up to 1250 degrees celsius to reach the required shape and is then rolled in a rolling mill to reshape them into reinforced bars.

Quenching

The heated steel bars are then cooled down or ‘quenched’ by a rapid cooling process which causes the material to avoid attaining certain undesirable properties. After the steel is processed and made into reinforced bars, there is a certain time frame during which the material may acquire undesirable properties. The rapid cooling of the steel is known as quenching of steel-reinforced bars. Quenching reduces the window of time during which the material is thermodynamically favourable towards attaining undesirable characteristics such as crystallisation of the material. Quenching prevents the steel from forming into a crystalline structure.

Self-tempering

After the quenching process, the material cools down and the core of the bar is at a higher temperature than the surface. The heat is transferred from the core to the outer surface of the bar. As a result, the outer structure is tempered. This self-tempering process causes the formation of a ring made of martensite and bainite and the outer surface is known as tempered martensite.

Atmospheric cooling

After the self-tempering process is completed, the bars are laid out on a cooling bed at normal temperature. This is done to level the difference between the hardened surface and the soft inner core. After reaching normal temperature, the core attains a ferrite-pearlite structure. Atmospheric cooling makes the TMT bar more weldable and the core is ductile.

This concludes the manufacturing process of TMT steel bars.

Please check out:

Srujana T

shora

posted on Mar 27, 2020 12:30:03 PM