You have no items in your shopping cart.

Post Requirement

Powder coating is a finishing process that consists of dry powder being used as a surface coating. Unlike paint, that takes a while to dry after being applied, powder coating is electrostatic, and can be applied smoothly in the presence of an electric current and then cured with heat. The powdered material is made up of a thermoplastic polymer that makes it hard and longer-lasting than traditional paint. This polymer is combined with resins, pigments, levelling agents, more additives, etc. All the materials are mixed after melting, then cooled down and made into its powder form.

What are different powder coating processes?

Electrostatic Spray Deposition

ESD method is most commonly used which involves using a spray gun to shower all the powder particles on the desired surface. The powder particles are negatively charged and then sprayed towards the material’s surface through a compressed air spraying technique which sprays the powder with a high electrostatic charge. There are several different kinds of nozzles that are used to spray the surface which depends upon the regularity of the paint and the kind of application it is used for.

Electrostatic Magnetic Brush Coating(EMB)

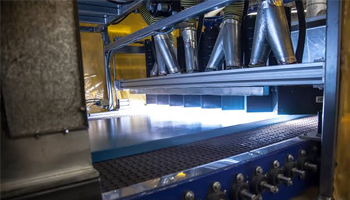

EMB coating is a method that is useful for an application on flat surfaces. The process involves the usage of a roller that applies powder of thickness ranging between 5-100 micrometres depending upon the application and usage. This method is mostly used in the steel, paper board, aluminium and sheet industries that require coating applications.

Electrostatic Fluidised Bed Coating

In this method, a chargeable electrostatic medium is placed inside a bed with powder material on it. The powder material when charged starts lifting itself from the bed into the fluidised air forming a cloud of charged powder particles above the bed. When a grounded material is placed on the bed, the charged particles automatically attach themselves to the surface through the charged cloud.

Curing

When a thermoregulated powder is exposed to high temperatures, it melts and chemically reacts to form a heavier polymer whose structure consists of a layered network. These powders are generally cured at a range of 200 degrees Celsius however, they may vary according to the manufacturers’ specifications. This curing process where powders are exposed to elevated temperatures that allow them to melt to achieve the desired chemical properties is also known as crosslinking.

How durable is powder coating?

The powder coating process can be used for many different products that are applicable in our daily lives. It can protect anything ranging from substances used in the kitchen to heavy machinery in industries. When compared to paint, it is more durable while still providing a pleasant finish. Powder coating is unaffected by chipping, wear and tear, scratch-resistant and fade-proof. The quality of the coating does not diminish as quickly when exposed to harsh weather, sunlight, moisture, etc.

What are the advantages of powder coating over other applications?

- Powder coating provides a thicker coating application without slumping down like paint.

- Powder coating looks almost the same on all applications including vertical, horizontal, slanted surfaces, etc., whereas painting can change the look of the surface depending upon its size, shape, etc.

- The curing process is very fast when compared to the drying time it takes for a painting application.

- Powder coating is environmental-friendly with no release of Volatile Organic Compounds(VOCs) into the atmosphere.

Please check out:

Srujana T