You have no items in your shopping cart.

Post Requirement

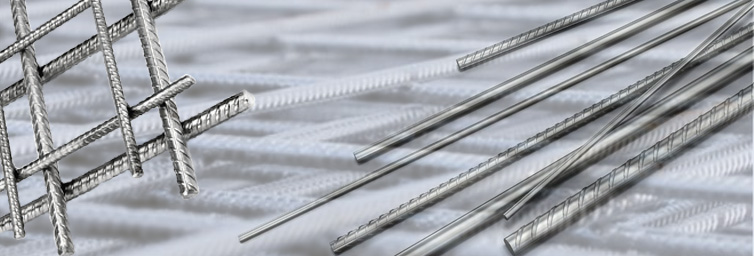

Steel in various forms is an essential material for construction. Different types of reinforcement bars, prestressing wires and strands, rolled steel sections and light-gauge steel sections are the primary forms of steel that are generally used in building construction.

Steel bars of many shapes and grades or strengths. These bars are of specified tensile strength, used for R.C to develop good bond strengths with concrete and also used for fabrication of grills, gates, etc.

There are various types of steel available in the market like mild steel, torsteel, TMT bars, etc. The following types of bars are commonly available in the market for reinforced concrete construction:

Hot Rolled Steel

Hot rolled steel bars are of four types:

The first type is the traditional mild steel bars (MS bars) produced by hot rolling. They are called mild steel plain bars which are hot rolled as round bars with a smooth surface.

Mild steel bars are available in two trades, Grade I and Grade II. The strength of Grade I is slightly higher than that of Grade II. These bars are more resistant to corrosion than torsteel bars.

The second type is the hot rolled mild steel ribbed bars, which consists of ribs on them. These ribs considerably increase the bond strength of the bars. Bars with ribs are called Rebar’s or ribbed bars, which are likely to be confused with HYSD bars, are not recommended to use in R.C works.

The third type is the hot rolled high strength ribbed bars produced by hot rolling and got by micro alloying which is of high strength. These rods are known as the hot rolled high yield strength deformed bars or HYSD bars, which are now replaced by TMT bars.

Cold Twisted Deformed Bars (Torsteel)

CTD bars were the first high strength bars used in India. These bars are first hot rolled out of high-grade mild steel, with three or more parallel straight ribs on it.

Cold twisted bars are easily identified in the field. As the projections were rolled straight on the bars in hot rolling, they will form a helic around the bars in cold twisting. Cold twisting introduces residual stresses in the steel.

These bars corrode much quicker than other bars, which are not recommended for use in many advanced countries.

TMT bars

Thermo-mechanically Treated Reinforcement Bars are produced by sudden quenching of red hot steel bars by a spray of water can produce steel bars with high strength at the surface with a core of mild steel.

The final result is a structure with tempered martensite on the periphery and a fine-grained ferrite-pearlite structure at the centre zone. These bars are also rolled with ribs (rebar’s) to increase the bond strength of the bars.

TMT-CRS (corrosion resistant) are also available in the market. The corrosion resistance is achieved by the addition of corrosion resistant elements like copper, phosphorous and chromium.

TMT bars are more corrosion resistant than other torsteel bars and are highly recommended to use in R.C works. These bars are available in four grades - Fe 415, Fe 500, Fe 550 and Fe 600.

Welded Wire Fabrics

These are called as fabrics and consist of weld mesh produced from medium tensile steel drawn out from diameter mild steel bars. The strength of these wires is higher than that of mild steel.

These wires are available in different widths in rolls, which are very much used in partitions, fencing, etc. and sometimes in R.C slab construction.

Storing of Reinforcements

Steel bars should be stored properly to avoid corrosion and distortion by keeping them off the ground and should also provide enough support so that they do not bend. In monsoons, some cover should be provided to these bars to keep off the rain. Bars of separate diameters should be stored as separate lots.

Inspection of Reinforcement before using in Construction

All reinforcements for R.C. Construction should be free from oil, paint, grease, loose rust, loose mild scale and other matter likely to impair the bond strength of the concrete.

Oil can be removed by washing with petrol. The rods when bent into hooks should be free from cracks or splits as it indicates brittle steel.

To know the quality of the steel, the test certificates from the steel factory should be obtained or it should be tested in an approved laboratory.

Check Out: Brick Masonry, Role of Reinforcement in Construction

Technically Reviewed by Rajesh Pagadala, MS, Founder & CEO - BuildersMart. Written by Vani paspula, Content Manager.

Vani Paspula

SUNIL GEORGE

posted on Sep 7, 2021 11:04:56 AM