You have no items in your shopping cart.

Post Requirement

Corrosion is the process of eroding of the top layer of metals as a result of an electrochemical reaction with the environment. When metals are exposed to moisture or wetness, an orangish discolouration known as rust forms on the surface of the metal. This causes deterioration and the gradual destruction of the metal, if not treated effectively. The study of prevention of corrosion and its treatment is known as Corrosion Engineering.

There are many forms of corrosion. The most common types are explained below.

General Attack Corrosion

This the most common type of corrosion which is also treatable. Also known as uniform attack corrosion, this phenomenon occurs when the entire surface of a metal is exposed to air or a wet surface which results in complete damage of the metal. General attack corrosion generally results in the most amount of destruction to the material however, it can be treated. Hence, it is also known to be the safest form of corrosion.

Galvanic Corrosion

Galvanic corrosion is a phenomenon that occurs when two distinct metals come in contact with each other through an electrolyte. One metal acts as a cathode while the other metal behaves like an anode. The rate of corrosion of the anode metal is amplified while the cathode metal takes longer to deteriorate. Galvanic corrosion can occur only when both the metals are placed in an electrolyte that is susceptible to corrosive action when electricity is passed through it.

Concentrated Corrosion

While general attack corrosion occurs on the entire surface of the metal, concentrated corrosion, also known as localised corrosion occurs on a particular area of the metal. It is of several types namely,

- Crevice Corrosion

- Pitting Corrosion

- Filiform Corrosion

1)Crevice Corrosion

As the name suggests, this type of corrosion occurs in cramped spaces otherwise known as crevices. This occurrence is common in areas which are stagnant and out of reach of preventive sealants such as cracks, gaps between contact areas, underseals, areas beneath piles, etc.

2)Pitting Corrosion

This type of corrosion occurs when a small area on the metal’s surface is subjected to a certain amount of moisture which causes this area to become anodic in nature. Galvanic corrosion occurs on this concentrated spot and can cause decay of the metal up to the extent of failure. Pitting is usually difficult to spot as it occurs in minuscule areas at critical points and is often found out only after the failure of the structure.

3)Filiform Corrosion

Filiform corrosion is a kind of corrosion that occurs in crevices when water spreads to the surface in cases such as underneath painted surfaces where the liquid is accumulated. It appears in the form of threadlike structures or filaments that are randomly distributed. It is also known as Underfilm corrosion or Filamentary corrosion.

High-Temperature Corrosion

Corrosion that occurs as a result of a chemical attack on the surface of the metal at high temperatures that usually range up to 750 degrees Fahrenheit or 400 degrees celsius. High-temperature corrosion can also occur due to carbonisation, high-temperature oxidisation and sulfidation.

Flow Accelerated Corrosion

When the surface of the metal is exposed to flowing water, the top layer which is also the protective oxide layer is eradicated due to the fast flow of the water causing corrosion and further degeneration of the metal. Few types of flow accelerated corrosion are:

- Impingement

- Cavitation

- Erosion assisted corrosion

1)Impingement

Impingement is a form of corrosion that is caused due to the impact of the rapid flow of water against the surface of metal causing deterioration of the material. This can cause significant damage to equipment in chemical industries, power plants, etc.

2)Cavitation

Cavitation is a type of corrosion that is caused as a result of the eruption of gas bubbles on the surface of the metal. This occurs when there is a sudden and unexpected release of pressure on the surface area caused by hydrodynamic fluid conditions.

3)Erosion assisted Corrosion

Erosion assisted corrosion is the loss of the top layer of metal due to the striking effect of particles suspended in a fast-flowing liquid, gas, slurry, etc. The erosion of the layer wipes off the protective oxidised layer which results in corrosion of the metal.

Intergranular Corrosion

This type of corrosion occurs at a granular level near the grain boundaries of the metal. It usually occurs when there is adulteration in higher quantity at the borders of the material. Thus, making the corners of the metal more susceptible to corrosion. This process is known as intergranular corrosion.

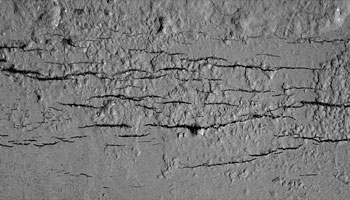

Environmental Cracking

Environmental cracking is a form of corrosion that occurs as a result of environmental factors surrounding the metal which causes the material to corrode. There are several types of corrosion that occurs due to environmental elements. They are:

- Corrosion fatigue

- Hydrogen-induced cracking

- Liquid metal embrittlement

- Stress corrosion cracking

1)Corrosion Fatigue

Corrosion fatigue is the process of metal degradation or ‘fatigue’ of the metal due to its exposure to corrosive surroundings. Most metals are exposed to a certain amount of stress during their lifecycle where they are prone to corrosive environments.

2)Hydrogen induced cracking

This phenomenon is caused when a high concentration of hydrogen is exposed to the surface of a metal which causes withering of the top layer of the material.

3)Liquid metal embrittlement

Liquid metal embrittlement occurs when the surface of a metal is exposed to certain liquid metals which causes a loss in the tensile ductility property of the material making it brittle in nature and causing fractures.

4)Stress Corrosion Cracking

As the name suggests, stress corrosion cracking is the widening of cracks that were previously formed as a result of being exposed to a corrosive environment. This can cause the unexpected failure of the metal especially at high temperatures.

Fretting Corrosion

Fretting corrosion is a result of stress being applied on the uneven or rough surface of metal including repeated vibrations, wear & tear, etc. Fretting corrosion usually occurs on machinery related to rotation and similar applications where the material is subjected to repeated vibrations.

De-Alloying

De-alloying, also called selective leaching is a process where an alloy metal loses its reactive property and regains the stable element of another element which is non-corrosive in nature.

Please check out:

Construction and Demolition Waste: Where does it go?

Srujana T